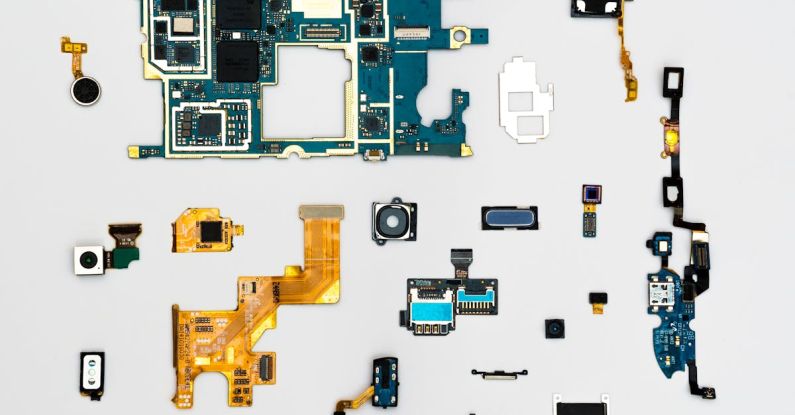

The Manufacturing Industry is undergoing a significant transformation with the integration of robotics into its operations. Gone are the days when manufacturing floors were filled solely with human workers diligently assembling products. Today, robots have become an integral part of the manufacturing process, revolutionizing the way products are made. This shift towards automation has brought about numerous benefits and challenges, shaping the future of the manufacturing industry in unprecedented ways.

**Enhanced Efficiency and Productivity**

One of the most significant impacts of robotics in the manufacturing industry is the enhanced efficiency and productivity it brings. Robots are capable of working around the clock without breaks, fatigue, or errors, leading to a substantial increase in production output. They can perform repetitive tasks with precision and consistency, leading to higher quality products and reduced waste. This improved efficiency allows manufacturers to meet increasing consumer demands while keeping costs in check.

**Improved Safety for Workers**

The introduction of robotics in manufacturing has also led to improved safety for human workers. Robots are designed to handle hazardous tasks that may pose risks to workers, such as working with chemicals, heavy machinery, or in extreme temperatures. By delegating these tasks to robots, companies can minimize the occurrence of workplace accidents and ensure the well-being of their employees. This shift towards a safer working environment not only protects workers but also boosts morale and productivity.

**Flexibility and Adaptability**

Another key benefit of robotics in the manufacturing industry is the flexibility and adaptability they offer. Modern robots are equipped with advanced sensors and programming that allow them to quickly adapt to changes in the production process. They can be easily reprogrammed to switch between different tasks or product lines, enabling manufacturers to respond swiftly to market demands and fluctuations. This flexibility also allows for the customization of products without the need for extensive retooling, making manufacturing processes more agile and cost-effective.

**Cost-Effectiveness and ROI**

While the initial investment in robotics technology may be significant, the long-term cost savings and return on investment (ROI) are substantial. Robots can perform tasks at a faster rate and with higher precision than human workers, leading to reduced labor costs and increased efficiency. Additionally, the automation of processes can help manufacturers minimize errors, rework, and waste, further driving down production costs. Over time, the cost-effectiveness of robotics in manufacturing becomes evident through improved productivity, quality, and competitiveness in the market.

**Challenges and Considerations**

Despite the numerous benefits of robotics in the manufacturing industry, there are also challenges and considerations that companies need to address. The integration of robotics requires significant upfront capital investment, as well as ongoing maintenance and training costs. Companies must also consider the impact of automation on the workforce, as the introduction of robots may lead to job displacement for some workers. Striking a balance between automation and human labor is crucial to ensuring a sustainable and ethical approach to manufacturing.

**The Future of Manufacturing with Robotics**

As technology continues to advance, the role of robotics in the manufacturing industry will only grow in importance. The integration of artificial intelligence (AI) and machine learning with robotics will further enhance automation capabilities, allowing for more complex tasks to be performed with ease. Collaborative robots, or cobots, will also become more prevalent, working alongside human workers in a seamless and efficient manner. The future of manufacturing with robotics is bright, offering endless possibilities for innovation, efficiency, and growth.

**In Summary**

Robotics are revolutionizing the manufacturing industry, bringing about enhanced efficiency, improved safety, flexibility, and cost-effectiveness. While challenges exist, the benefits of integrating robotics into manufacturing processes far outweigh the drawbacks. As companies continue to embrace automation and technology, the future of manufacturing with robotics looks promising, paving the way for a more sustainable, productive, and competitive industry.