Quality control measures are an essential component of maintaining high standards in manufacturing processes. Implementing effective quality control measures not only ensures the consistency and reliability of products but also enhances customer satisfaction and loyalty. In today’s competitive market, manufacturers need to prioritize quality control to stay ahead of the competition and build a strong reputation for their brand. Let’s explore some key strategies that manufacturers can implement to enhance their quality control processes.

Establish Clear Quality Standards

Setting clear quality standards is the foundation of any effective quality control system. Manufacturers should define specific criteria and specifications for each product to ensure consistency and uniformity in the manufacturing process. By establishing clear quality standards, manufacturers can minimize variations in products and identify deviations promptly. This proactive approach helps in preventing defects and ensuring that only products that meet the defined quality criteria are released to the market.

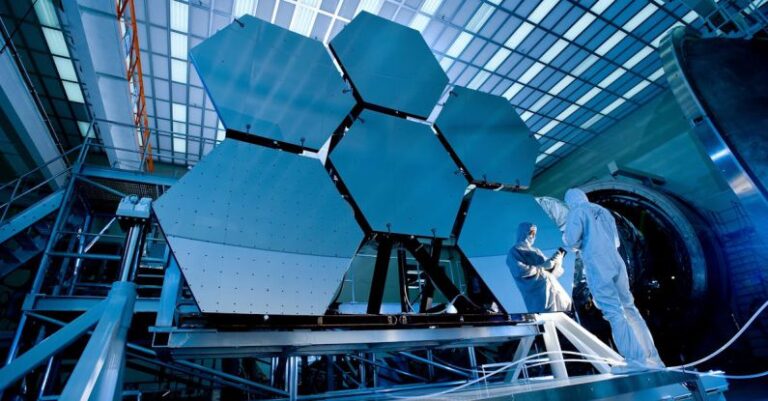

Utilize Advanced Technology

Incorporating advanced technology tools and systems can greatly enhance the effectiveness of quality control measures in manufacturing. Automated inspection systems, data analytics, and artificial intelligence can help manufacturers monitor and analyze production processes in real-time, identifying potential defects or inconsistencies before they escalate. By leveraging technology, manufacturers can streamline their quality control processes, improve efficiency, and reduce the likelihood of human errors.

Implement Regular Training Programs

Investing in employee training and development is crucial for maintaining high-quality standards in manufacturing. Regular training programs on quality control protocols, procedures, and best practices can help employees understand the importance of quality control and their role in ensuring product quality. Well-trained employees are better equipped to identify quality issues, adhere to quality standards, and contribute to continuous improvement efforts within the organization.

Emphasize Supplier Quality Management

Quality control measures should not be limited to in-house production processes but should also extend to suppliers and vendors. Implementing robust supplier quality management practices can help manufacturers ensure that raw materials, components, and finished products meet the required quality standards. By establishing clear quality requirements for suppliers, conducting regular audits, and providing feedback on quality performance, manufacturers can strengthen their supply chain and minimize the risk of receiving substandard materials.

Implement Statistical Process Control

Statistical process control (SPC) is a powerful tool that manufacturers can use to monitor and control production processes effectively. By collecting and analyzing data on key process parameters, such as temperature, pressure, and dimensions, manufacturers can identify trends, patterns, and variations that may indicate potential quality issues. Implementing SPC enables manufacturers to take corrective actions proactively, optimize processes, and prevent defects from occurring, ultimately leading to higher product quality and customer satisfaction.

Conduct Regular Quality Audits

Regular quality audits are essential for evaluating the effectiveness of quality control measures and identifying areas for improvement. Manufacturers should conduct internal audits, third-party audits, and customer audits to assess compliance with quality standards, regulatory requirements, and customer expectations. By conducting thorough quality audits, manufacturers can identify gaps in their quality control processes, implement corrective actions, and drive continuous improvement across the organization.

Strive for Continuous Improvement

Continuous improvement is a fundamental principle of quality management that manufacturers should embrace to enhance their quality control measures continually. By fostering a culture of continuous improvement, encouraging employee feedback and suggestions, and implementing lean manufacturing principles, manufacturers can drive innovation, optimize processes, and deliver higher-quality products to customers. Continuous improvement is a journey, not a destination, and manufacturers should strive to evolve and adapt to changing market dynamics and customer preferences.

In conclusion, implementing quality control measures is essential for manufacturers to ensure product quality, customer satisfaction, and business success. By establishing clear quality standards, leveraging advanced technology, investing in employee training, emphasizing supplier quality management, implementing statistical process control, conducting regular quality audits, and striving for continuous improvement, manufacturers can enhance their quality control processes and maintain a competitive edge in the market. Quality control is not just a task; it is a mindset that should be ingrained in the organizational culture to achieve long-term success and sustainability.